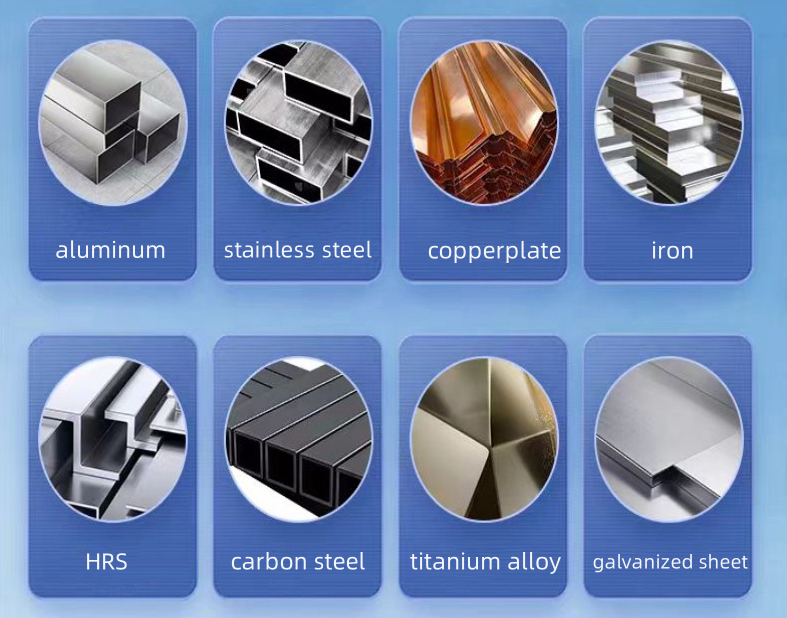

1. Stainless hlau

Stainless hlau muaj ib tug siab coefficient ntawm thermal expansion, thiab nws yog nquag overheating thaum vuam. Thaum tshav kub-tshuaj tiv thaiv yog me ntsis loj, nws yuav ua rau muaj teeb meem loj deformation. Txawm li cas los xij, cov cua sov tsim los ntawm lub tshuab nqa laser vuam thaum lub sij hawm tag nrho cov txheej txheem vuam yog tsawg. Ua ke nrog cov thermal conductivity tsawg, siab zog nqus tus nqi thiab melting efficiency ntawm stainless hlau, zoo tsim, du thiab zoo nkauj welds tuaj yeem tau tom qab vuam.

2. Carbon hlau

Ordinary carbon steel tuaj yeem welded ncaj qha los ntawm tes tuavFiber laser vuam tshuab, cov nyhuv yog piv rau stainless hlau welding, thiab cov tshav kub cuam tshuam qhov chaw me me, tab sis thaum vuam nruab nrab thiab siab carbon steel, qhov seem kub yog siab, yog li nws tseem yuav tsum tau vuam ua ntej vuam. Preheating thiab kub preservation tom qab vuam kom txo tau kev ntxhov siab thiab tsis txhob tawg. Ntawm no peb tuaj yeem tham txog lub tshuab welding txias. Nruab nrab thiab siab carbon steel tuaj yeem welded los yog kho ntawm qeeb ceev nrog txias vuam thiab cam khwb cia hlau vuam hlau. Nyob rau hauv cov nqe lus ntawm kev tswj qhov kub thiab txias, tswj qhov kub thiab txias, lub tshuab txias welding tuaj yeem qhia kev tuav tes laser welding ntau npaum li cas ntawm cov khoom cua sov tom qab vuam.

3. Tuag hlau

Nws yog tsim rau vuam ntau hom hlau tuag, thiab cov nyhuv vuam zoo heev.

4. Aluminium thiab aluminium alloy

Aluminium thiab aluminium alloys yog cov ntaub ntawv zoo heev, thiab cov porosity yuav tshwm sim hauv lub pas dej ua ke los yog hauv paus thaum lub sij hawm vuam. Piv nrog rau yav dhau los cov ntaub ntawv hlau, txhuas thiab txhuas alloys muaj ntau dua qhov yuav tsum tau rau cov tsis, tab sis ntev li ntev raws li cov kev xaiv welding tsis tsim nyog, weld seam nrog tib yam txhua yam khoom raws li lub hauv paus hlau yuav tau.

5. Copper thiab tooj liab alloy

Lub thermal conductivity ntawm tooj liab muaj zog heev, thiab nws yog ib qho yooj yim los ua kom tiav kev nkag mus thiab ib nrab fusion thaum lub sij hawm vuam. Feem ntau, cov khoom siv tooj liab yog rhuab thaum lub sij hawm vuam txheej txheem los pab vuam. Ntawm no peb tab tom tham txog cov khoom siv tooj liab nyias.Handheld laser vuam tshuabtuaj yeem ncaj qha Vuam, vim nws cov concentrated zog thiab ceev vuam ceev, tsis tshua muaj kev cuam tshuam los ntawm cov thermal conductivity ntawm tooj liab.

6. Vuam ntawm cov khoom sib txawv

Lub tes tuav laser vuam tshuab tuaj yeem nqa tawm ntawm ntau yam hlau tsis sib xws, xws li tooj liab-nickel, nickel-titanium, tooj liab-titanium, titanium-molybdenum, tooj dag-tooj liab, qis carbon steel-tooj liab thiab lwm yam hlau tsis sib xws. Laser welding tuaj yeem ua tau raws li txhua yam kev mob (gas lossis kub).

Handheld laser vuam tshuabTam sim no yog ib qho khoom siv dav hauv kev lag luam vuam, feem ntau vim hais tias txawm hais tias cov cuab yeej no zoo li kim dua, nws tuaj yeem txuag nqi zog heev. Tus nqi ua haujlwm ntawm welders kuj kim heev. Siv cov khoom no daws cov teeb meem ntawm kim thiab nyuaj nrhiav neeg ua haujlwm welders. Ntxiv mus, lub handheld laser vuam tshuab tau yeej unanimous qhuas los ntawm ntau txhiab tus neeg muas zaub vim nws lub neej ntev kev pab cuam thiab tsawg zog noj.

Yog hais tias koj xav paub ntau ntxiv txog laser tu, los yog xav yuav lub zoo tshaj plaws laser tu tshuab rau koj, thov tso lus rau peb lub website thiab email rau peb ncaj qha!

Post lub sij hawm: Dec-25-2024